Concrete mix design can be described as the method for choosing the perfect components of concrete as well as the relative proportions of concrete mix according to the ratios of cement, sand and coarse aggregates so as to form concrete of specific minimum strength and longevity as cost effectively as possible. The concrete mix design proportions are demonstrated with volume or mass. The water-cement ratio is generally stated in mass.

Concrete mix design is essential to attain target strength in structures. By knowing the quantity of cement in the mix, it becomes possible to specify various things like permeability, shrinkage, workability, pumpability, stampability, and stainability.

The objective of concrete mix design is to make sure that the most optimal ratios of the materials are used to satisfy the need of the structure to be developed. Mix design should consider the following points :-

To obtain the desirable applicability in the plastic phase

To obtain the desirable minimum strength in the hardened phase

To obtain the desirable strength in the specified environmental conditions

To form concrete as inexpensively as possible

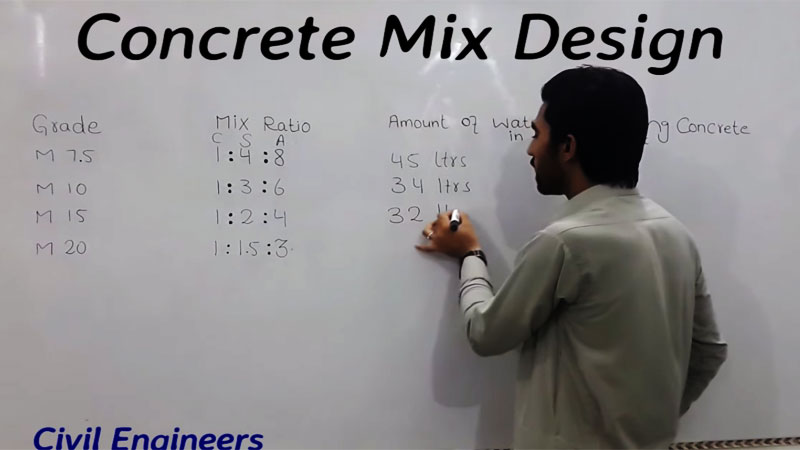

This construction video tutorial briefly explains the process for concrete mix design. The values for the grade, mix ratio of concrete and amount of water for blending concrete in (50 Kg) cement are given below :-

Grade :-

M 7.5

M 10

M 15

M 20

Mix Ratio (C : S : A)

1 : 4 : 8

1 : 3 : 6

1 : 2 : 4

1 : 1.5 : 3

C = Cement, S = Sand and A = Aggregate

The amount of water for blending concrete in (50 Kg) cement (in litres)

45 litres for grade M 7.5 and mix ratio 1:4:8

34 litres for grade M 10 and mix ratio 1:3:6

32 litres for grade M 15 and mix ratio 1:2:4

30 litres for grade M 20 and mix ratio 1:1.5:3

Watch the following video to get more details.

Video Courtesy : Civil Engineers